Table of Contents

Highlights

- Modular and eco-friendly battery recycling methods are making it easier to recover lithium and other materials at a lower cost and with less environmental impact.

- AI and automation are improving battery recycling sorting, disassembly, and safety across recycling facilities.

- Policy momentum is pushing industries to meet battery recycling content quotas and invest in closed-loop systems.

In a world rapidly moving toward electrification, the question of what happens to all the lithium-ion batteries after their first life has become more urgent than ever. This July, the conversation around battery recycling has shifted from theoretical potential to real-world innovation. New technologies and processes are not just solving technical challenges, but they are also rewriting the playbook on how we think about materials, waste, and sustainability. From startup labs in California to pilot plants in Germany and scalable systems in India, the breakthroughs this month point toward a greener, more circular future for energy storage.

A Modular Revolution in Lithium Recovery

In Burlingame, California, a young company named Electroflow is gaining recognition for doing something once considered improbable: extracting battery-grade lithium using electrochemical cells that operate at room temperature. Their system, trialed at a geothermal site, achieves recovery rates as high as 96 percent while using far less energy and water than traditional methods.

Instead of relying on massive refineries and harsh chemicals, Electroflow’s technology can be deployed in modular units, offering a nimble, more decentralised way to recover lithium and convert it directly into cathode-ready material. It’s not just more efficient, it’s more democratic.

Greener Chemistry from Down Under

Across the Pacific, an Australian startup called Iondrive has been drawing attention for its innovative approach to hydrometallurgy. Traditionally, extracting valuable metals from old batteries required corrosive acids and toxic reagents. Iondrive, developed at the University of Adelaide, replaces those with organic solvents that are safer, cleaner, and reusable.

By removing the environmental sting from recycling, they’re showing that industrial-scale solutions do not have to come at the expense of ecosystems. Construction of their first pilot plant is already underway, powered by strong investor interest and support from the Australian government.

Europe’s Leap into Direct Recycling

Europe, too, is witnessing a remarkable uptick in direct recycling technologies. In the UK, Atilium and Imperial College London have partnered to regenerate cathode materials directly from spent batteries, bypassing the need to break them down into raw elements. Early tests suggest the performance of these recycled materials actually matches or even exceeds that of their newly mined counterparts.

At the same time, German startup tozero has honed in on graphite, the unsung hero of battery chemistry. Their pilot plant promises to recover thousands of tonnes of high-purity graphite annually by 2027, slashing both carbon emissions and costs.

Germany and Switzerland Refine the Process

In the heart of Germany, Duesenfeld is taking battery recycling to the next level with a process that does not rely on heat or combustion. Their low-temperature vacuum drying technology eliminates the generation of dangerous hydrofluoric acid gas, a significant hazard in conventional battery recycling. What is even more impressive is that they can recover more than 90 percent of a battery’s original materials, including challenging components such as solvent residues and foils.

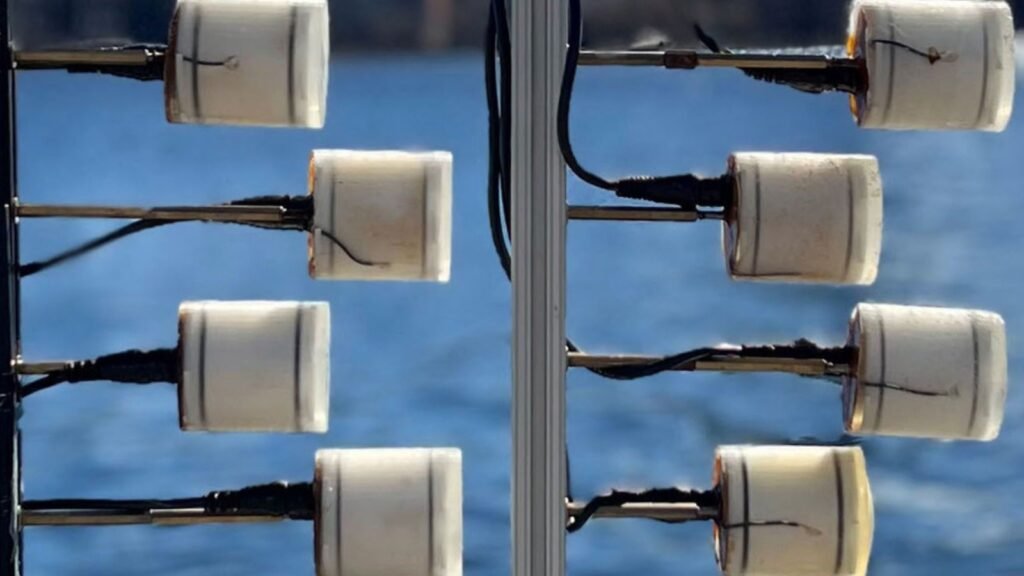

Just across the border in Switzerland, the electric vehicle company Kyburz is pushing boundaries differently. Rather than shredding and melting battery packs, their process surgically disassembles them. By preserving electrode structures, Kyburz ensures that valuable materials remain intact and can be reused. Their technique offers an efficient, energy-light alternative, especially for lithium-ion phosphate (LFP) batteries, which are often overlooked in traditional recycling efforts.

Redwood Materials Leads the Charge in the U.S.

In North America, Redwood Materials continues to play a leading role in closing the battery loop. The company, founded by former Tesla executive J.B. Straubel, is already handling over 70 percent of the continent’s lithium-ion battery waste. What makes Redwood unique is its vertically integrated model, which collects old batteries, recovers critical minerals, and then feeds them back into the supply chain as new cathode and anode materials.

Their recent expansion into energy storage is another bold move. In June, Redwood helped launch a 63 megawatt-hour battery system made entirely from recycled materials, which now powers a data center that supports AI computing. It is the kind of scale and impact that speaks volumes.

Redwood has also struck a notable partnership with Lime, the global micromobility giant, to recycle the batteries from e-scooters and e-bikes across three continents. The recovered materials — nickel, cobalt, and lithium — are being refined and reused, rather than being discarded in landfills. It is a small but significant move towards embedding circularity into urban transport ecosystems.

High-Speed Recovery at the University Lab Bench

Even in academic circles, progress is evident. At Rice University, researchers have pioneered a technique known as Flash Joule Heating. It is as fast as the name implies: applying intense pulses of energy to battery waste, they can vaporise impurities and extract elemental metals in just seconds. This high-efficiency, solvent-free approach has achieved recovery rates nearing 98 percent, which is an astonishing feat in the recycling world. However, this method is still in the early stages of industrial deployment. Its potential to scale quickly and cleanly is undeniable.

More intelligent Sorting, Safer Disassembly

Other supporting technologies are quietly improving the entire recycling process behind the scenes. Artificial intelligence is being used to sort batteries with uncanny precision, identifying chemistries and models through visual and chemical data. Research groups have even developed machine-learning tools that can detect battery age and charge status, allowing for safer handling and optimised discharging before recycling. As more automation is introduced into dismantling and sorting lines, human labor becomes safer, and overall efficiency improves.

Policies Begin to Catch Up

Policy support is finally catching up to the pace of innovation. The European Union has introduced stringent targets for minimum recycled content in batteries, requiring companies to include at least 6 percent lithium and 16 percent cobalt from recycled sources by the end of the decade. These rules also set performance benchmarks for recycling plants, demanding that at least 65 percent of battery weight be recovered by 2025. In the United States, new federal incentives are encouraging domestic recycling capacity, while states like California and New York are experimenting with extended producer responsibility laws.

Conclusion

As July 2025 draws to a close, it feels like the conversation about battery recycling has matured. No longer a footnote to the electric vehicle boom, recycling is now a front-and-centre challenge and opportunity. Companies are not only responding to the moment, they’re anticipating the next one. They’re designing batteries that are easier to disassemble, investing in software that tracks a battery’s full lifecycle, and weaving sustainability into the DNA of next-generation materials.

The road ahead won’t be without its hurdles. Scaling up pilot plants, navigating regulatory red tape, and building consumer awareness remain ongoing tasks. However, with such momentum, July 2025 may well be remembered as the month when the recycling revolution transitioned from speculation to reality. What was once a problem to be solved is now an industry in full bloom, one that promises not only to reduce waste but to reshape how we use and reuse the materials that power our world.